- #ULTIMAKER CURA M1 1080P#

- #ULTIMAKER CURA M1 INSTALL#

- #ULTIMAKER CURA M1 UPDATE#

- #ULTIMAKER CURA M1 DOWNLOAD#

- #ULTIMAKER CURA M1 FREE#

Improved onboarding so it is easier to add your first cloud printer or a non-UltiMaker printer.

#ULTIMAKER CURA M1 UPDATE#

Added a new way to update profiles by adding a Save/Compare Settings Button in custom window.Added quality type to slice meta-data so it can be displayed in the Ultimaker Digital Factory.Added tooling to automatically generate translation files to reduce the chance of human error.Updated Load Project window with a new design.Replaced mentions of Ultimaker by UltiMaker to correctly reflect the merger.Fixed the order in which concentric top/bottom patterns are printed.

#ULTIMAKER CURA M1 DOWNLOAD#

It will be live and you can ask any questions to our CTO, Miguel Calvo.This release does not yet contain the new tree support implementation by You can download a special Cura version for that here.

#ULTIMAKER CURA M1 FREE#

We’re hosting a free tech demo on February 7.

#ULTIMAKER CURA M1 1080P#

Reliable bed tilt compensation (no more thumbscrews) 2.4 and 5 GHz Wi-Fi A 1080p camera (mounted higher for a better view) Compatibility with 280+ Marketplace materials Compatibility with S5 project files (no reslicing needed) And a whole lot more The UltiMaker S7 also includes quality of life improvements: We also reversed the front fan direction (fewer plastic hairs, less maintenance), made the print core door magnets stronger, and add a sensor that helps avoid flooding. This effectively makes it much harder to not achieve a perfect first layer, improving overall print success. The re-engineered print head has an inductive sensor which reduces noise when probing the build plate. Along with that, 4 pins and 25 magnets make it easy to replace the flex plate perfectly – even with one hand. But we also don’t recommend using or adhesion structures for UltiMaker materials (except PC, ’s PC). Not only do you not need tools to pop a printed part off. A PEI-coated flexible steel build plate makes a big difference to productivity. The build stack has also been completely redesigned. To further enclose the build chamber the S7 only has one magnetically latched door. This filters the exhaust air of every print and also improves build temperature stability. It now includes an integrated Air Manager. The UltiMaker S7 is built on the success of the UltiMaker S5 and its design decisions were heavily based on feedback from customers.

Or rewatch our launch event to learn more about Ultimaker Cura 5.0 beta:

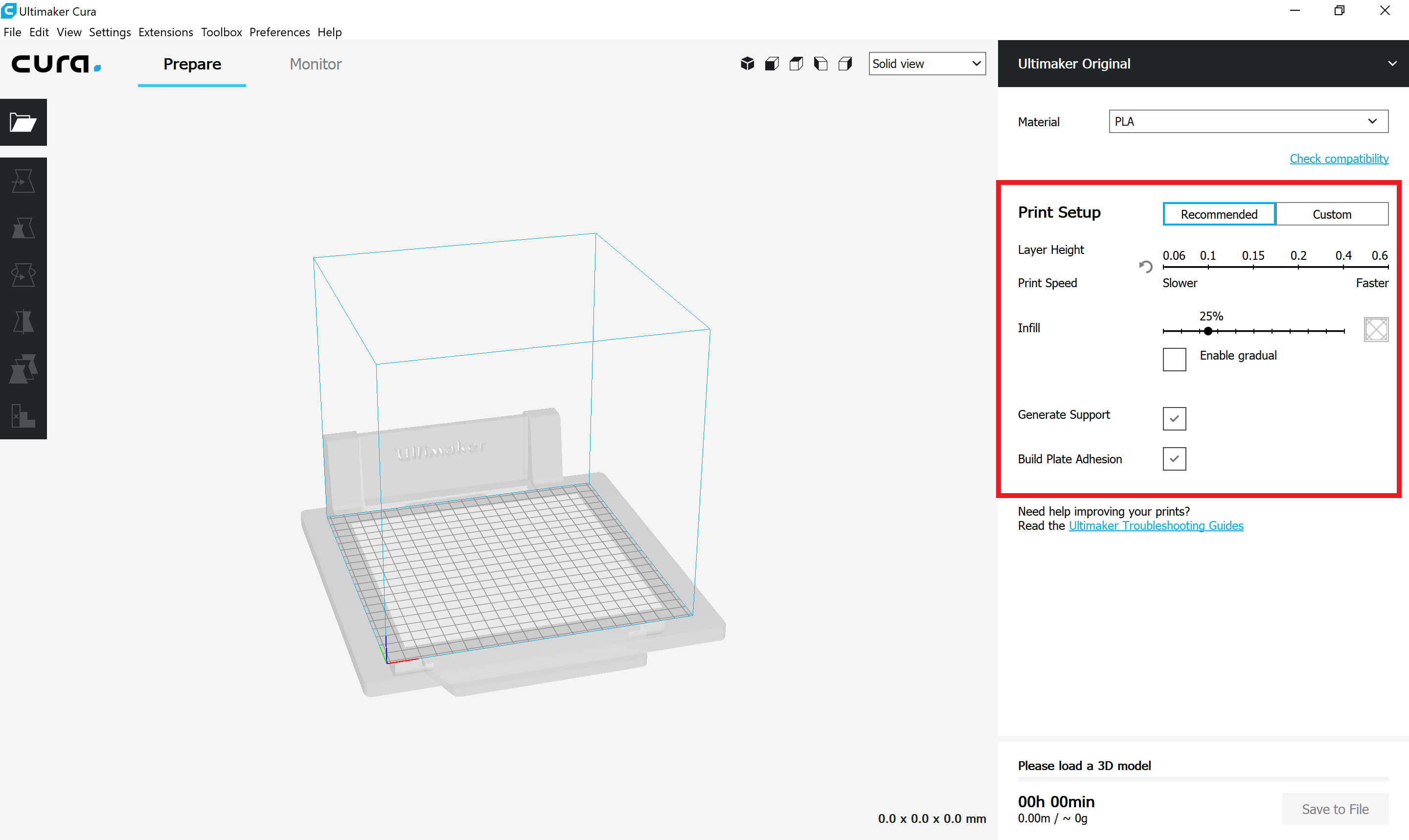

#ULTIMAKER CURA M1 INSTALL#

The UI has been improved and it’s now easier and faster to find and install plugins and material profiles. We have streamlined the workflow for accessing the Ultimaker Marketplace inside of Ultimaker Cura. The following improvements have also been included: Your printed parts will now have fewer internal gaps which means they’ll not only look better, but they’ll be stronger as well. This issue has been completely solved with the latest release. In certain case s (such as with extremely small details) areas of less than one line thick would not be able to print at all. This meant that when slicing a file, if part of the print was two-and-a-half lines thick, Ultimaker Cura would generate two lines and leave a small gap between them. In the past, sliced files would use a consistent line wi d th, with the exact width depending on the nozzle diameter and the line width settings used. This new engine uses variable line widths when preparing files for printing, meaning you can now print thin and intricate parts more accurately and with greater strength. After multiple special beta releases to test the Arachne Engine, the new slicing Engine is finally here. Today we release the Ultimaker Cura 5.0 beta.

0 kommentar(er)

0 kommentar(er)